In response to today’s disinformation from the anonymous Substack account “Lies are Unbekoming” in its article “Steel to Powder: on 9/11”

Excerpt:

7. The destruction of evidence, such as the quick removal of steel debris, is often brought up. How do you think this impacted the investigation?

It did not happen. This is another nonsense claim designed to make us believe there were mountains of steel debris to remove. There wasn’t. Most of the towers were converted to fine powder since dustification eliminated most of the steel. As Dr. Wood wrote, “Impossible as it may seem, most of the steel from those towers also vanished, literally turned into dust. From Day One of clearing ground zero, around-the-clock photos of the demolition were taken. Did you see any photos of the 3000 truckloads of steel being driven away?

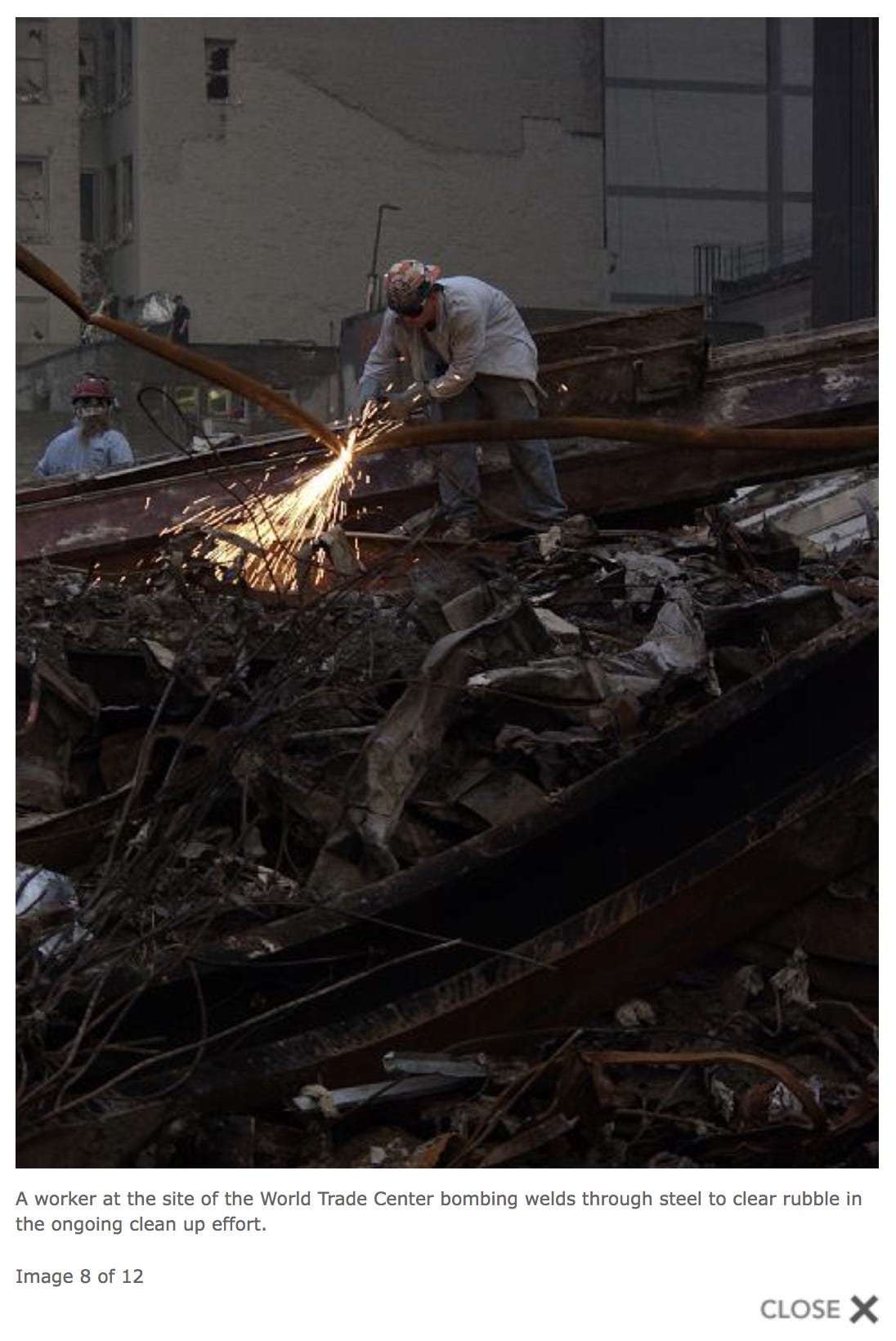

A timeline begins below from original sources. There’s a lot of other images of steel beams available to anyone who wants to look for them. Dr. Judy Wood is a liar, and that’s just all there is to it. The steel was quickly removed and exported to melt down to prevent inspection which would have shown how the metal beams failed.

This is just a partial summary of information. There’s a lot of other information available on how the steel was processed, and yes, plenty of images.

Apparently Dr. Judy Wood wants to cover up what really happened. I don’t bother to argue with the anonymous sock puppet accounts here on Substack accounts devoted to Judy Woods disinformation. If you want to use a real, verifiable name, OK. Otherwise I just block these accounts.

I recommend watching the Rumble video below on how the debris were processed at Fresh Kills landfill.

September 11-12, 2001. https://exhibitions.nysm.nysed.gov/wtc/recovery/index.html

Over the hours and days after 9/11, activity at Ground Zero quickly turned from a rescue effort to recovering the remains of the lost, the possessions of both the dead and the living, and crime scene evidence. At the same time, a discreet recovery operation was underway at the Fresh Kills facility on Staten Island. It was at this facility, where teams worked long tedious hours at a disheartening task, that a major, but largely untold, part of the story of September 11 happened.

By nightfall on September 11, Mayor Rudolph W. Giuliani, with approval from Governor George E. Pataki—decided to reopen the Fresh Kills facility, giving it a crime scene designation so that it could receive what remained of the World Trade Center. Closed since March 2001, the Fresh Kills facility, whose Dutch-derived name means “freshwater stream,” was reopened just after midnight. By 2:00 a.m. on September 12, trucks began to arrive with loads of steel and solid material from Ground Zero. New York Police Department and Federal Bureau of Investigation Evidence Response Teams arrived in the early morning hours to begin the thorough inspection of the materials and take on a threefold mission: find as many human remains as possible, recover personal effects, and search for evidence from the terrorists.

September 13-14, 2001. This speech was delivered by Wendy Neu to the Empire State Chapter of ISRI on November 28, 2001.

Only after HNSE, Metal Management and ISRI came forward was their serious consideration given to recycling all of the steel and metal scrap. However, there were serious problems to overcome. The most critical was removing the estimated 300,000 tons of steel and over 1 million tons of debris from Ground Zero in the quickest manner without hampering rescue and recovery efforts. Amazingly, within 48 hours of September 11th the city had started removing material from Ground Zero and by the 14th, 3 days later; over 10,000 tons of debris and scrap had been moved to Fresh Kills Landfill. Shortly thereafter, the rate increased to 7,000 tons per day to the Fresh Kills Landfill. This involved 6-700 truckloads a day leaving Ground Zero. Some by truck thru the Battery Tunnel and over the Verrazano Bridge and the balance by truck transferred to barges on the Fresh Kills Landfill.

September 16, 2001.

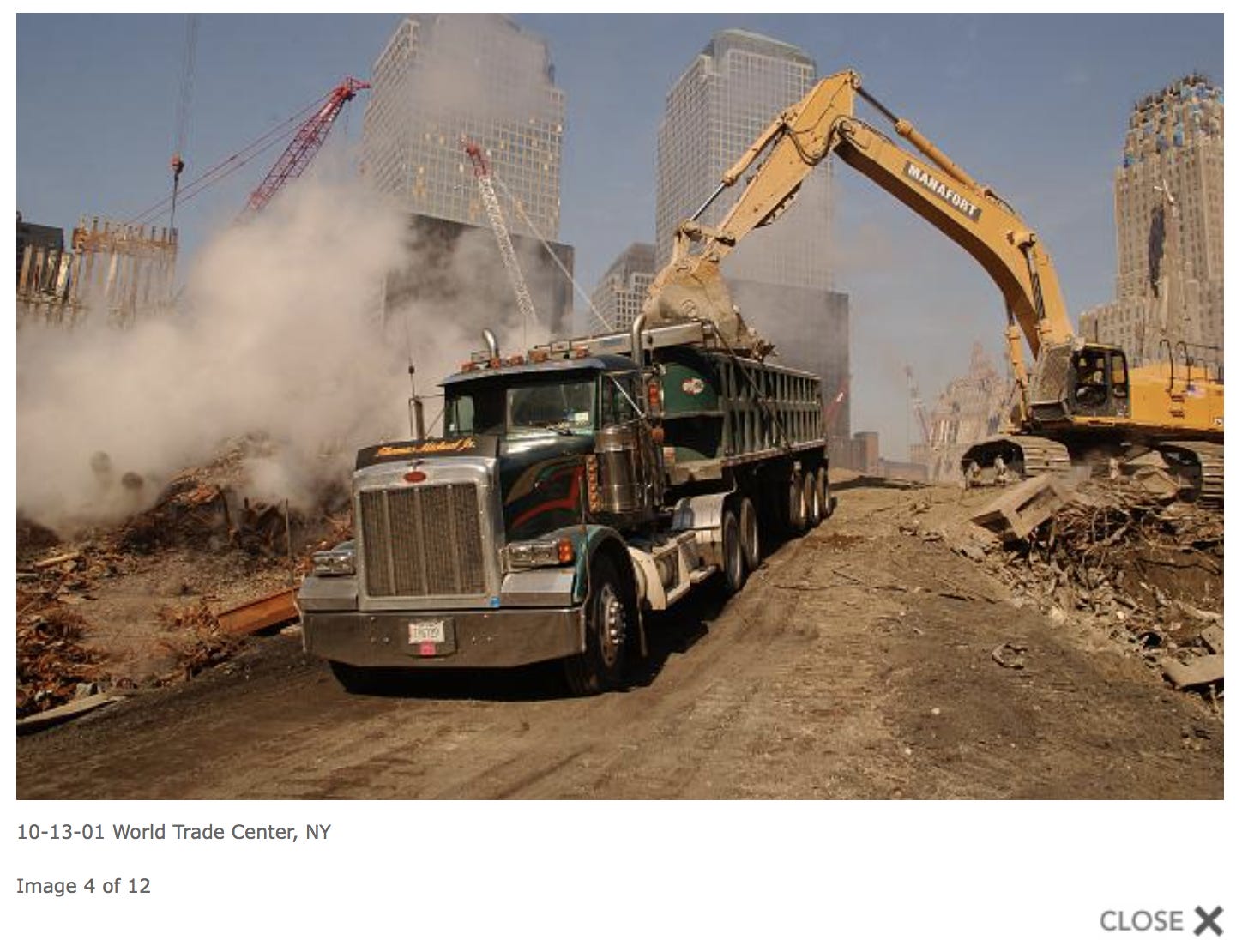

September 19, 2001. https://www.yachtsinternational.com/owners-lounge/pier-to-peer

Eight days after the terrorist attacks of 9/11, Manafort Brothers won the contract to assist with the demolition of the remains of the World Trade Center and to collapse several buildings around it. It was six months’ worth of grueling and heartbreaking work, according to Manafort, who recounted the weight of seeing personal items in the rubble and conversing with family members who came to pay their respects. In the early stages, with no hotels open in that part of the city, Manafort docked his first Broward, 92-foot Independence, at Liberty Landing Marina in New Jersey, for him and his workers to live aboard while commuting to the site.

September 21, 2001. This speech was delivered by Wendy Neu to the Empire State Chapter of ISRI on November 28, 2001.

On September 21st, HNSE agreed under our preexisting contract with the Department of Sanitation to take on the task of recycling all the steel and mixed scrap at the landfill, we finally got a chance to see for ourselves what had already been shipped there from Ground Zero. What we saw has never before been seen and hopefully will never again. Over 35,000 tons of steel beams from the WTC towers were stacked in remarkably neat rows, approximately 20 feet high. Many of the beams were twisted and distorted as though made of rubber or wax. Some This speech was delivered by Wendy Neu to the Empire State Chapter of ISRI on November 28, 2001. beams were over 6” thick and bent like pretzels. Structural engineers, who are experts in steel structures that have suffered earthquakes and explosions claimed to have seen nothing like this before and could not imagine the kind of pressure and heat required to do this kind of damage. Unfortunately, the beams were only the beginning. On the top of the landfill covering about 20 acres, local law enforcement had set up a make shift forensic recovery operation where every bucketful of debris from Ground Zero was sorted by hand. Within the next 30 days they would be processing this material with conveyors and finger screens to separate fine dirt, steel, and concrete but still spreading everything out and inspecting every pound of material.

September 22, 24, 2001. This speech was delivered by Wendy Neu to the Empire State Chapter of ISRI on November 28, 2001.

We expect to complete burning operations at the landfill mid to late December when we will have prepared and shipped the original 35,000 tons plus of steel beams that was shipped there prior to October 1. In late September, a system was established to market the steel beams thru an RFP in (2) 25,000-ton lots. On the 22nd of September the first contracts were awarded to Metal Management and HNSE for 25,000 tons each, to be shipped within a 30-day period in 400-1000 ton barge loads directly from Ground Zero. The first barges started arriving at our Claremont facility on September 24th and we completed the contract on November 7th. Subsequent to the earlier bid another 60,000 tons was auctioned in (3) 20,000-ton lots in October. Metal Management was awarded 2 of the lots with Blandford Land Clearing awarded the remaining lot.

September 23, 2001. This speech was delivered by Wendy Neu to the Empire State Chapter of ISRI on November 28, 2001.

Within 24 hours of visiting Fresh Kills for the first time we mobilized the first of what was soon to be an army of people and equipment at that site. By the 23rd of September, 2 days later, we were moving cut up steel beams from the landfill. Initially, we started with a Komatsu 650, and a Le Bounty 175 shear, which we moved from a tank demolition job in Brooklyn. Within a few days we started an (8) man burning crew and on the 27th of September we went to a (13) man crew. In addition, we set up burning stations, decontamination showers, an office trailer, generator, water tanks, and a water truck for dust suppression. To assist in supervising and to ensure strict compliance with OSHA i.e. making sure respirators were properly used, showers taken, clothes changed etc, as well as to collect air samples, blood samples, and test for asbestos on the steel beams, we employed a safety organization. To service the site we mobilized an additional 3 mobile shears, an MSD 100, MSD 175, and MSD 200 right out of the factory. All mounted on Komatsu excavators (2) 650’s and (1) 750, plus three Komatsus, two with grapples and one with a magnet. At any one time we may have as many as 15 subcontractor haulers moving an average of 150 truck loads per day of both prepared and unprepared material to our facility in Claremont, Jersey City.

The MSD 100, pictured below, opens to 38”, according to La Bounty. The MSD 200 opens to 51.”

LaBounty MSD Mobile Shears are specifically designed for scrap processing, demolition work, and road and bridge reconstruction. Mobile Shears can cut a variety of materials including H- and I- beams, railcars, plate, tanks, pipe, round stock, wire, rebar and concrete, brick or block.

October 8, 2021. This speech was delivered by Wendy Neu to the Empire State Chapter of ISRI on November 28, 2001.

By October 8th we also started shipping the mixed unprepared scrap as well. We averaged 16- 1900 tons per day, about 400 tons of steel beams and up to 1200 tons of unprepared mixed scrap to our Claremont facility. The mixed scrap is a combination of broken steel beams, light iron, rebar, nonferrous metal from innumerable sources and everything metallic that you might find in a 100 story building. Because it is such a mixed package and there is no segregation at the landfill, 75 percent of the material must be sheared and less than 25 percent is shreddable. As you can imagine our main task at the landfill is to minimize the amount of debris, concrete and dirt that is mixed in with the scrap. We learned early on that the mindset of a landfill operator is very different from our own. After several visits to the landfill we observed that once the mixed scrap was examined forensically the inclination was to just bury it. At least several thousand tons, perhaps up to 10,000 tons was buried before we were able to convince the operators that this was not waste and should be set aside.

October 13, 2001.

New York Times, A Search for Clues In Towers' Collapse; Engineers Volunteer to Examine Steel Debris Taken to Scrapyards, February 2, 2002.

Cranes with super magnets toss smashed washing machines, junked cars and rusted train tracks like paper clips. Trucks with tires as tall as an elephant slop through the stinking, oil-fouled mud, dumping new loads with an unceremonious crash.

It is here at this Jersey City scrapyard, in front of a different pile of wreckage, that Anamaria Bonilla, a structural engineer, falls to her knees.

With the sleeve of her sweatshirt, she rubs furiously at the rusty surface of a 36-foot-long World Trade Center column that has caught her trained eye. As a cluster of other engineers with charts, tape measures and Palm Pilots gather around her, the hint of a code painted onto the steel more than 30 years ago surfaces.

Rolling over almost on her back to seek other markings she knows must be there, Ms. Bonilla slides her head between the underside of the column and the mud and reads aloud what she finds.

''One-oh-one,'' she says. ''The 101st floor,'' says a fellow investigator, David F. Sharp, after he also squeezes into the gap, confirming the markings Ms. Bonilla found. It was a potentially important discovery, but in part a result of happenstance.

From the moment the two towers collapsed on Sept. 11, engineers and other experts have been struggling to answer the monumental questions of exactly why and how the buildings, designed to sustain a jet impact, completely collapsed. But despite promises of a broad federal investigation, and after weeks of calls from victims' families and others to halt the destruction of the steel that could hold all sorts of clues, the half-heroic, half-comic scenes at the Jersey City scrapyard continue to play out.

Small teams of engineers plot slightly mad dashes, like mountain goats, into mounds of steel to claim pieces of tower columns. The engineers time their forays to avoid being crushed. Indeed, Ms. Bonilla made her find while the scrapyard workers were on their lunch break.

Through it all, the engineers profess optimism that they are catching and saving what is most useful. But they concede that there is no way of saying for sure; an unknown number of steel columns has been sent off to mills as far away as Asia without ever having been examined or saved.

The organizers of the steel recovery effort will not say how many pieces in total have been set aside for future study, saying only that it is more than 100 from among the hundreds of thousands of World Trade Center steel parts. But without a doubt, the teams surveying have made some important discoveries.

The steel column identified last Wednesday by Ms. Bonilla, with its brackets, bolts and two pairs of winglike steel plates still attached, is a potentially critical discovery. It ran three stories from the 98th to the 101st floor on the exterior face of one tower, just above the zones struck by jets laden with fuel. Now that it has been found -- and spray-painted with the word ''Save'' in florescent orange paint -- tests can be conducted to determine whether heat or stress or some design or material flaw might have let it fail.

Another crumpled steel member set aside at a Keasbey, N.J., scrapyard has markings clearly showing that it ran on the east face of the north tower from the 92nd to the 95th floor, in the center of one impact zone. Pieces of steel have also been found that were apparently melted and vaporized not solely because of the heat of fires, but also because of a corrosive contaminant that was somehow released in the conflagrations. And unexpectedly cracked washers in crucial connections in the towers are being closely scrutinized.

The organized steel recovery effort is one piece of a three-tiered investigation. The American Society of Civil Engineers, in coordination with the Federal Emergency Management Agency, has set up a panel of engineering and fire experts who are assembling photographs, witness interviews and other data to try to determine why the towers collapsed. The effort, organized by the Structural Engineers Association of New York, is the team's primary source of raw steel evidence from the site.

Volunteers from the Structural Engineers Association visited ground zero first in early October and identified a handful of steel samples they wanted to save. But it was not until the start of November that three separate teams started to visit the steel yards on a regular basis. Since then, about 40 visits have been made to the three recycling yards and the Fresh Kills Landfill in Staten Island, where some steel is also being sent.

Much of the effort is focused on trying to find steel that was at or above the floors rammed by the hijacked jets. The towers collapsed from the top down and the fires were concentrated in these areas, so the presumption is that the answer to why they fell down should be found by examining the steel from these spots.

When the towers were built, markings were inscribed on the steel columns to indicate their exact positions. But with the damage from the fire and collapse, many of those markings cannot be found. Instead, the engineers measure the width of the steel: the higher it is in the building, the thinner it is. For example, plates that are three-eighths of an inch thick -- used to connect columns -- were used only above the 80th floor.

The engineers, who more typically are in Manhattan offices designing bridges or high rises, visit the scrapyards on a sporadic schedule, sometimes taking vacation days to make up for the absences from their regular jobs. The teams -- about 20 people are involved in all -- are made up of a mixture of some of the city's most established structural engineers, like Edward DePaola, a principal at Sevrerud Associates, and younger engineers, like Ms. Bonilla, who works for a California-based engineering company.

Ms. Bonilla, who spent many days on rooftops during her years working as a carpenter before she became an engineer, is one of the most aggressive spotters, bounding into the steel piles even before the others have climbed out of a rusty Chevrolet truck that drives them around the Jersey City scrapyard, called Hugo Neu Schnitzer East.

Other members in the group handle the detailed measurements and take photographs of each piece of steel they intend to save. On some expeditions to the yards, not a single piece considered worth saving is identified. On other days, a whole cache of potentially important scraps is found.

''Every day is productive, even if you don't find anything you have a sense that at least you looked,'' said Mr. DePaola, whose company served as the structural engineer for projects including the Denver International Airport and the Reuters Building at 3 Times Square that recently opened.

Like doctors performing an autopsy after a mysterious death, the evidence these engineers collect is the raw material that after scrutiny in laboratories around the United States could provide the answer and have an impact far beyond the World Trade Center. Even before pieces of recovered steel are sent off to a laboratory for analysis, the samples tell a story to the practiced eye of Ramon Gilsanz, a structural engineer and partner at Gilsanz, Murray, Steficek in Greenwich Village.

On one piece found last month, extremely detailed markings were found: Tower A, 92-95, 252. That means it came from the north tower, between the 92nd and 95th floors, about 30 feet from the southeast corner, on the east face of the building. The plane that struck this building came in at just about this level, but it struck the north face.

This piece, 21 feet long, is mangled and torn at one end and severely chewed up near the center, where there are burn marks and the scumlike whitish remnants of the fireproofing that once clung to the steel. The stubs of brackets that once held up floors still protrude from what had been the interior surface of the columns. Tiny, twisted scraps of the aluminum that formed the gleaming facade of the tower cling to the steel.

The condition of floor studs on the steel hints to Mr. Gilsanz that the floor at this spot in the upper reaches of the north tower collapsed not because of a faulty weld, but for some other reason that investigators have still not determined.

Another piece of steel recently discovered has a series of steel washers that are cracked, a worrisome sign to Mr. Sharp, whose company, TurnaSure L.L.C., designs super strong fasteners that have been installed in some of the world's tallest buildings. ''I would not anticipate this happening, and I want to know what it did,'' he said, adding that a cracked washer significantly reduced the strength of a bolted connection.

Perhaps the deepest mystery uncovered in the investigation involves extremely thin bits of steel collected from the trade towers and from 7 World Trade Center, a 47-story high rise that also collapsed for unknown reasons. The steel apparently melted away, but no fire in any of the buildings was believed to be hot enough to melt steel outright.

A preliminary analysis of the steel at Worcester Polytechnic Institute using electron microscopes suggests that sulfur released during the fires -- no one knows from where -- may have combined with atoms in the steel to form compounds that melt at lower temperatures.

Steel Beam loaded onto Pier 25. 2:19 mark. https://rumble.com/v5dd66a-world-trade-center-debris-at-fresh-kills-landfill-on-staten-island.html

Video from Corbett Report;

Transcript:

ERIK LAWYER: "9/11 was the greatest loss of life and property damage in U.S. fire history. This should of been the most protected, preserved, over-tested and thorough investigation of a crime scene in world history. Sadly it was not. What was it? Well, we know from their (NIST) admission the majority of the evidence was destroyed. Like Richard (Gage) said, (in) 22 years of experience I've seen a lot of crime scenes, I've never seen anything like this in my life.I was out at the site, I saw trucks leaving faster than anywhere I've ever seen but I accepted it at the time and for years I accepted it because it was a recovery and rescue operation and that's normal to have something like going. Again, we'd never seen anything like it but that was expected.

"What I didn't know for years was what was going on behind the scenes was that evidence was being destroyed when it was shipped off. By their own admission, the NIST investigation of Tower 7 had no physical evidence. How do you investigate a crime when you've destroyed all the evidence? It doesn't make sense.

"They also admit that they refused to test for explosives or residue of thermite. Now this is what I'm going to go into real quickly is that there are national standards for for an investigation. That's what all of us are asking for. An investigation that follows national standards and holds people accountable."

March 15, 2002.

Undated:

Undated:

May 31, 2002 - July 26, 2002. https://exhibitions.nysm.nysed.gov/wtc/recovery/notes.html

Barge and Truck Operation

Barges were 130 feet long x 30 feet wide x 15 feet deep

Each barge carried 650 tons of material

Barge operation was completed on May 31, 2002

13,096 truckloads containing 218,181 tons supplemented the barge operation

The recovery operation was officially completed on July 26, 2002, at 1:00 p.m.

END

Huh. No mention of the tremendous heat visible in the ruins for almost 6 weeks.

How can we be sure that anything told or presented to us about 9/11 is not propaganda?

1. We know that the footage of the destructions of the twin towers and WTC-7 is fake ... cos they tell us Revelation-of-the-Method style.

https://petraliverani.substack.com/p/911-the-movie

2. Ditto we also know that the imagery of Ground Zero is fake.

Faking the rubble - https://cluesforum.info/viewtopic.php?t=489

They have us all chasing our tails with what exactly brought the buildings down, presenting propaganda for each of five methods: fire, DEWs, thermite/nanothermite, nukes/mini nukes and good old controlled demolition (CD).

Even though I think we have to plump for CD as it is the only known method for bringing down high rise steel frame buildings and there is nothing compelling provided for any of the others, they still presented p-r-o-p-a-g-a-n-d-a for CD to maximise the tail-chasing.

Toppling the towers: why five purported methods?

https://petraliverani.substack.com/p/toppling-the-towers-why-five-purported